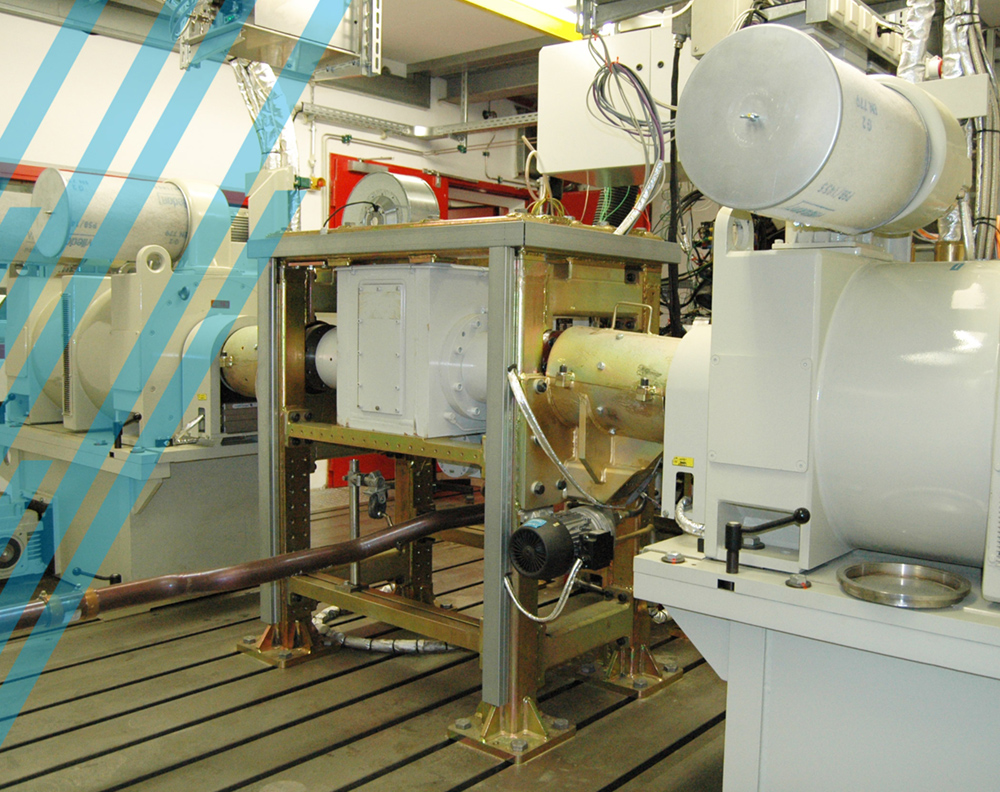

Test stands

Our test bay comprises a total of 10 highly automated test benches where we can carry out continuous, parallel measurements of any duration in 24-hour operation. All test benches are equipped with the most state-of-the-art dynamometers as well as cooling and conditioning systems. This enables us to test any vehicle configuration under any static or dynamic road and environmental conditions, from simulating everyday journeys to material testing under extreme conditions.

- 9 engine test benches

- 1 single-axle powertrain test bench

- Multi-configuration model

Dynamometers

- Asynchronous machines on all test benches

- Engine testbeds: performance range up to 500 kW, 1,690 Nm, 10,000 rpm

Powertrain testbed: performance range up to 2 x 277 kW, 2 x 3,300 Nm, 3,250 rpm

Ancillary unit testing (generator, air conditioning compressor, hydraulic power steering pump, vacuum pump)

- Engine testbeds: performance range up to 500 kW, 1,690 Nm, 10,000 rpm

- 48V energy systems up to 32 kW

- with battery simulation

Automation and software

- FEV MORPHEE automation system

- Standard data acquisition rate: 1 kHz

Frequency for real-time applications on the powertrain test stand: 4 kHz

Redundant system architecture

- Standard data acquisition rate: 1 kHz

- Software: AVL FlexIFEM Indi, ETAS INCA, Vector CANalyzer

- Oracle database

- Automatic measurement data filing and -transmission

ASAM ODS data standard

- Automatic measurement data filing and -transmission

Cooling and conditioning

- Frontal airflow

- Intercooler

- Conditioning of intake and combustion air and fuel

- Motor standstill cooling

- with programmable cooling gradients

- Thermoshock facilities

- Automatic oil refill

Special measuring technology

Our facilities also feature highly specialised measuring and analysis systems which we can use to tailor our tests to your specific requirements. We can also rent the necessary equipment for you if your enquiry goes beyond our technical possibilities.

- Facility for dynamic online oil consumption measurements

- Combustion analysis systems

- Indicator systems

Peak pressure monitoring systems

Customer-specific systems

- Indicator systems

- Exhaust air analysis systems

- 5-component AMAs

Smoke emission test equipment

AVL Micro Soot Sensor

Particle count test equipment

- 5-component AMAs

- Vibration measurement equipment

- on all test stand drives

- Reilhofer early stage damage detection systems

- Flowmeters

- to calculate blow-by volume, air mass, volume of coolants and oil

Infrastructure

In addition to test stands, our location features a variety of workrooms and logistical facilities to transport, prepare and fill units under test, evaluate test results, perform repairs and much more. These additional facilities work with the test bay so as to guarantee the most efficient operations possible.

- Workshops and laboratories

- Mechanical workshop

Pallet workshop

Electrical workshop

Engine assembly and dismantling

Engine diagnostics

Measuring room

Photo laboratory

Calibration laboratory

- Mechanical workshop

- Tank storage

- 8 fuel tanks

Entry controls

- 8 fuel tanks

- Logistics

- Own collection and drop-off service

We’re happy to assist you!

Contact

Phone: (0 84 58) 32 43 – 0

E-Mail: